-

Destacar

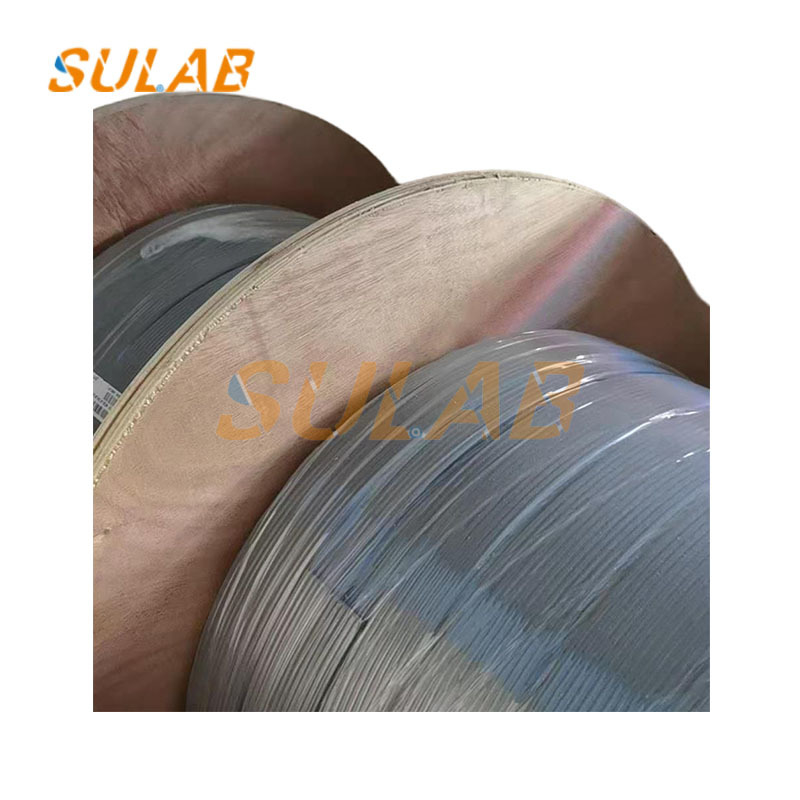

Sulab PV40 elevator steel belt

,40mm traction belt for elevators

,elevator spare parts steel belt

-

MarcaSulab

-

DescriçãoCinturão de elevador

-

ModeloPV40

-

MOQ1pc

-

TransportçãoTNT, UPS, DHL, FedEx, Air, Sea

-

PacotesCarton, caixa de madeira, paletes etc

-

Tempo de entregaNormalmente 2-3 dias úteis após o pagamento

-

GarantiaUm ano

-

Método de pagamentoBanco da empresa, Western Union, Alibaba, Paypal etc

-

MarcaSulab

-

Número do modeloPV40

-

Quantidade de ordem mínima1

-

Tempo de entrega2-3 dias úteis

-

Termos de pagamentoT/T, Western Union, MoneyGram

Sulab PV40 Elevator Steel Belt 40mm Traction Belt

Elevator Steel Belt 3300 Traction Steel Belt STM-PV30/PV40/PV50/PV60 Elevator Main Machine Steel Belt

Product Specifications

| Brand | Sulab |

| Description | Elevator belt |

| Model | PV40 |

| MOQ | 1PC |

| Transportion | TNT, UPS, DHL, Fedex, Air, Sea |

| Packages | Carton, Wooden case, Pallet etc |

| Delivery Time | Normally 2-3 working days after payment |

| Warranty | One year |

| Payment Method | Company Bank, Western union, alibaba, Paypal etc |

Product Description

The Schindler PV40 is a Poly-V traction steel belt (STM) specifically designed for Schindler elevators, offering superior performance and reliability.

Specification Parameters

The "40" in PV40 indicates a width of 40 millimeters. With a minimum initial breaking force of 56kN, this can be verified by checking the model marking and minimum initial breaking force marking on the wedge sleeve.

Material Characteristics

Constructed with fine steel wires (steel core) wrapped in composite polymer materials (typically polyurethane), this belt offers:

- Excellent wear resistance and tensile strength

- Stable performance in extreme temperatures (-30℃ to 80℃)

Performance Advantages

- High Safety: Flat structure design increases traction sheave contact area for greater friction and slip prevention. Eliminates derailment risks associated with traditional rope grooves. Multiple belts provide load capacity far exceeding operational requirements.

- Energy Efficiency: 20% lighter than steel ropes with 10%+ energy savings. Higher flexibility allows smaller traction sheave diameters for compact, efficient transmission systems.

- Riding Comfort: Minimized noise and vibration through polyurethane flexibility and compact drive host design.

- Low Maintenance: No lubrication required. Polyurethane wrapping prevents elongation, breakage, and fraying. Reduced replacement frequency and simplified maintenance procedures.